Navigating Briggs & Stratton Intek engine repairs often begins with accessing a comprehensive PDF manual, offering vital guidance for technicians and DIY enthusiasts alike.

What is the Briggs & Stratton Intek Engine?

The Briggs & Stratton Intek engine represents a widely utilized series of small, overhead valve (OHV) engines, renowned for their durability and performance in diverse applications. Commonly found powering lawnmowers, pressure washers, generators, and other outdoor power equipment, the Intek engine family offers both single-cylinder and V-Twin configurations.

These engines are celebrated for their robust construction and relatively straightforward serviceability. However, even with their reliability, maintenance and occasional repairs are inevitable. Accessing a dedicated Briggs & Stratton Intek repair manual PDF becomes crucial for correctly diagnosing issues and performing effective repairs, ensuring longevity and optimal operation of the engine.

Importance of a Repair Manual

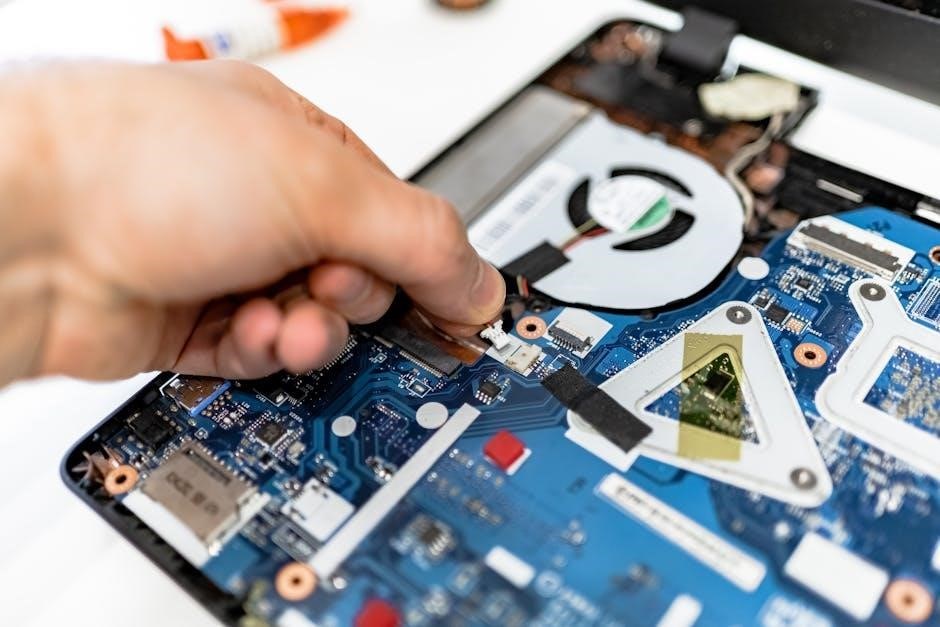

A Briggs & Stratton Intek repair manual PDF is indispensable for anyone undertaking maintenance or repairs. These manuals provide detailed, step-by-step instructions, accompanied by diagrams and illustrations, crucial for accurate disassembly, troubleshooting, and reassembly of the engine.

Attempting repairs without a manual risks improper procedures, potentially causing further damage or safety hazards. The manual details specific torque specifications, component locations, and safety precautions vital for a successful repair. Furthermore, a PDF format allows for easy access, printing of relevant sections, and convenient searching for specific information, streamlining the repair process and saving valuable time.

Locating the Briggs & Stratton Intek Repair Manual PDF

Finding the correct PDF manual involves checking the official Briggs & Stratton website or exploring reputable third-party download sites for your engine model.

Official Briggs & Stratton Website

The official Briggs & Stratton website is the most reliable source for authentic Intek engine repair manuals in PDF format. Typically, you’ll need your engine’s model number, type code, and serial number to pinpoint the exact manual required. These identifiers ensure compatibility and accurate repair information.

Navigating the site involves using their parts lookup tool or searching directly within the support/manuals section. While some manuals are available for free download, others might require a small purchase. Always verify the manual’s applicability to your specific Intek engine to avoid incorrect procedures. The website also offers troubleshooting guides and FAQs that can supplement the repair manual.

Third-Party Download Sites

Numerous third-party websites offer Briggs & Stratton Intek repair manuals as PDF downloads. However, exercise caution when utilizing these sources. The quality and accuracy of manuals found on these sites can vary significantly, and some may contain outdated or incorrect information.

Be wary of sites requesting excessive personal information or displaying suspicious advertisements. Always scan downloaded files with updated antivirus software to protect against malware. While potentially offering convenience, these sites often lack the official support and guarantee of accuracy found on the Briggs & Stratton website. Verify the manual’s details against your engine’s specifications before use.

Checking for Model-Specific Manuals

Briggs & Stratton Intek engines come in various models, and using a manual specific to your engine is crucial. Generic manuals may not cover all the nuances of your particular configuration. Locate your engine’s model number – typically found on the engine’s housing or a sticker.

When searching for a PDF repair manual, always include this model number in your search query. Many websites, including official and third-party sources, allow filtering by model. Confirm the manual explicitly lists your engine model before relying on its instructions. This ensures accurate repair procedures and avoids potential damage caused by incorrect guidance.

Understanding the Manual’s Structure

A typical Briggs & Stratton Intek PDF manual includes safety guidelines, detailed parts lists, troubleshooting steps, and comprehensive repair procedures for optimal engine care.

Safety Precautions

Before commencing any repair work on your Briggs & Stratton Intek engine, carefully review the safety section within the PDF manual. Disconnect the spark plug wire to prevent accidental starting, and always work in a well-ventilated area.

Fuel is highly flammable; avoid smoking or open flames near the engine or fuel tank. Wear appropriate personal protective equipment (PPE), including safety glasses and gloves, to shield against potential hazards like hot surfaces and chemicals.

Properly support the engine during maintenance to prevent it from falling. Be mindful of rotating parts and hot exhaust components. The manual emphasizes safe handling of tools and fluids, ensuring a secure and successful repair process.

Tools and Materials Required

The Briggs & Stratton Intek repair manual PDF details a comprehensive list of necessary tools; Standard items include a socket set, wrenches (metric and standard), screwdrivers (Phillips and flathead), pliers, and a torque wrench for precise tightening.

Specialized tools, like a valve spring compressor or a carburetor cleaning kit, may be needed depending on the repair. Essential materials encompass engine oil (specified by the manual), oil filter, spark plug, air filter, fuel filter, and carburetor cleaner.

Having a multimeter for electrical diagnostics and a compression tester is also highly recommended. Refer to the manual’s specific section for your engine model to ensure you have everything required before starting.

Engine Specifications

The Briggs & Stratton Intek repair manual PDF provides crucial engine specifications for accurate servicing. This includes displacement (cc), horsepower, torque (lb-ft), and compression ratio. Detailed information on valve clearances (intake & exhaust) is vital for optimal performance.

Ignition timing settings, spark plug gap, and recommended oil type/capacity are also clearly outlined. The manual specifies the correct fuel type and carburetor settings for various altitudes. Bore and stroke dimensions are included for engine rebuilds.

Furthermore, it lists the engine’s serial number ranges corresponding to specific model variations, ensuring you’re referencing the correct data for your particular Intek engine.

Common Intek Engine Problems & Repairs

The Briggs & Stratton Intek repair manual PDF details frequent issues like carburetor faults, ignition failures, and valve problems, alongside repair steps.

Carburetor Issues

The Briggs & Stratton Intek repair manual PDF dedicates significant attention to carburetor troubleshooting, as these are common sources of engine problems. Issues often stem from clogged jets, a dirty carburetor bowl, or a faulty fuel solenoid. The manual provides detailed diagrams illustrating carburetor disassembly and reassembly, crucial for cleaning and inspection.

It guides users through identifying and replacing worn gaskets and seals, preventing fuel leaks and ensuring proper air-fuel mixture. Step-by-step instructions cover adjusting the idle speed and mixture screws for optimal engine performance. Furthermore, the PDF manual emphasizes safety precautions when working with fuel, highlighting the importance of disconnecting the spark plug wire and working in a well-ventilated area.

Ignition System Troubleshooting

The Briggs & Stratton Intek repair manual PDF offers extensive guidance on diagnosing ignition system faults. It details procedures for testing the ignition coil, magneto, and spark plug using a multimeter and spark tester. Diagrams clearly illustrate the location of each component and their wiring connections, simplifying the troubleshooting process.

The manual explains how to check for a strong spark, identify a weak or intermittent signal, and pinpoint potential causes like a faulty coil or damaged wiring. It also covers procedures for adjusting the air gap between the magneto and flywheel for optimal performance. Safety warnings within the PDF emphasize disconnecting the spark plug wire before working on the ignition system to prevent accidental shocks.

Valve Adjustment Procedures

The Briggs & Stratton Intek repair manual PDF provides detailed, step-by-step instructions for valve adjustment. It emphasizes the importance of proper valve lash for optimal engine performance and longevity. The manual includes clear diagrams illustrating the valve train components and their relationship to the crankshaft.

It outlines how to determine top dead center (TDC) and accurately measure valve lash using a feeler gauge. Specific valve lash specifications are provided for various Intek engine models, ensuring correct adjustment. The PDF also details the procedure for loosening the valve adjustment nut and using the adjustment screw to achieve the correct clearance, ultimately improving engine efficiency and reducing wear.

Detailed Repair Procedures

The Briggs & Stratton Intek repair manual PDF expertly guides users through essential maintenance, like oil changes, spark plug replacements, and air filter servicing.

Oil Change and Filter Replacement

The Briggs & Stratton Intek repair manual PDF provides step-by-step instructions for performing essential oil changes and filter replacements, crucial for engine longevity. It details the correct oil type and capacity for various Intek engine models, preventing damage from improper lubrication.

The manual illustrates the location of the oil drain plug and filter, emphasizing proper tightening torques to avoid leaks or stripping threads. Diagrams clearly show how to safely remove and install the new filter, alongside guidance on disposing of used oil responsibly. Following these procedures, as outlined in the PDF, ensures optimal engine performance and extends its lifespan, saving on costly repairs down the line.

Spark Plug Replacement

The Briggs & Stratton Intek repair manual PDF offers detailed guidance on spark plug replacement, a common maintenance task for these engines. It specifies the correct spark plug type and gap settings for each Intek model, ensuring optimal combustion and engine performance.

The manual includes clear illustrations demonstrating how to safely access and remove the old spark plug, avoiding damage to the cylinder head. It emphasizes the importance of using a torque wrench when installing the new plug, preventing over-tightening or loosening. Proper spark plug maintenance, as detailed in the PDF, contributes to easier starting, improved fuel efficiency, and reduced emissions, ultimately prolonging engine life.

Air Filter Maintenance

The Briggs & Stratton Intek repair manual PDF highlights the critical role of air filter maintenance in engine longevity. It provides step-by-step instructions for inspecting, cleaning, and replacing the air filter, crucial for preventing debris from entering the engine.

The PDF details different air filter types used in Intek engines – foam, paper, and cartridge – and specifies the appropriate cleaning methods for each. It stresses the importance of regular inspection, especially in dusty environments, and outlines the signs indicating a filter replacement is necessary. Maintaining a clean air filter, as guided by the manual, ensures optimal airflow, efficient combustion, and protects the engine from premature wear.

Advanced Repair Topics

The Briggs & Stratton Intek repair manual PDF delves into complex repairs like engine overhauls, compression diagnosis, and intricate electrical system troubleshooting.

Overhaul of the V-Twin Engine

A complete V-Twin engine overhaul, detailed within the Briggs & Stratton Intek repair manual PDF, is a significant undertaking. The manual guides technicians through disassembly, inspection of critical components like pistons, connecting rods, and the crankshaft, and precise measurements for wear.

It emphasizes the importance of cylinder honing or boring, valve seat grinding, and meticulous cleaning of all parts. Torque specifications for reassembly are paramount, ensuring proper engine function and longevity. The PDF provides exploded views and step-by-step instructions, covering gasket replacement, oil sealing, and final engine testing procedures. Following the manual’s guidance minimizes errors and maximizes the success of a full engine rebuild.

Diagnosing and Repairing Low Compression

The Briggs & Stratton Intek repair manual PDF provides detailed procedures for diagnosing and rectifying low compression issues. It outlines a systematic approach, starting with a compression test to establish a baseline. The manual details how to interpret results and pinpoint potential causes – worn piston rings, scored cylinder walls, or leaky valves.

Repair procedures include valve lapping and seat grinding, cylinder honing or boring, and piston/ring replacement. The PDF emphasizes the importance of proper torque specifications during reassembly to maintain a tight seal. It also covers leak-down testing for precise identification of leakage points, ensuring effective and lasting compression restoration.

Electrical System Diagnostics

The Briggs & Stratton Intek repair manual PDF offers comprehensive guidance on diagnosing electrical faults. It includes detailed wiring diagrams, crucial for tracing circuits and identifying shorts or open connections. The manual explains how to test the ignition coil, magneto, and voltage regulator using a multimeter, providing specific resistance and voltage values for reference.

Troubleshooting steps cover issues like no spark, intermittent operation, and charging problems. The PDF details procedures for checking the flywheel key, safety switches, and wiring harness for damage. It emphasizes the importance of proper grounding and clean connections for optimal performance, ensuring a reliable electrical system and engine operation.

Using the PDF Manual Effectively

The Briggs & Stratton Intek repair manual PDF’s search function, printing options, and bookmark features enhance usability for quick access to vital repair information.

Search Functionality

The Briggs & Stratton Intek repair manual PDF boasts a robust search functionality, crucial for swiftly locating specific repair procedures or parts diagrams. Instead of manually flipping through hundreds of pages, users can input keywords – such as “carburetor adjustment,” “valve clearance,” or a specific model number – to pinpoint relevant sections instantly.

This feature dramatically reduces troubleshooting time, especially when dealing with complex engine issues. Effective use of the search tool requires understanding common terminology used within the manual. Experiment with different search terms and variations to ensure comprehensive results. The PDF’s search capability transforms a potentially lengthy repair process into a streamlined and efficient experience.

Printing Specific Sections

A significant advantage of the Briggs & Stratton Intek repair manual PDF is the ability to print only the sections needed for a particular repair. This conserves paper and toner, creating a focused and manageable resource. Rather than printing the entire manual, users can select specific pages detailing carburetor repair, ignition troubleshooting, or oil change procedures.

Most PDF viewers offer printing options allowing page range selection. This feature is particularly useful when working in a garage or outdoors, where keeping the entire manual clean and accessible can be challenging. Printing only relevant sections ensures you have the necessary information readily available without unnecessary bulk.

Bookmarks and Annotations

The Briggs & Stratton Intek repair manual PDF format excels in usability through features like bookmarks and annotations. Bookmarks allow users to quickly navigate to frequently referenced sections – valve adjustment, for example – streamlining the repair process. Annotations, such as highlighting key steps or adding personal notes, personalize the manual for individual needs.

These tools transform a static document into a dynamic resource. Technicians can mark diagrams for clarity or jot down troubleshooting observations directly within the PDF. This personalized approach enhances comprehension and efficiency, making the manual a valuable long-term asset for engine maintenance and repair.